In the last few years more autonomous tractors have rolled onto fields around the world. These new tractors are...

Precision Agriculture

Saving Time with Harvest Data Management Tech

A grain handling yard equipped with a SigmaGrain software system from Sigmasys. Photo: Sigmasys What are the benefits...

TELUS Invests $1 Million in Olds College Smart Farm

TELUS Agriculture is investing $1 million in the Olds College Smart Farm to support the development, acceleration and...

Seek and Destroy: The Control Of Herbicide-Resistant Weeds Through Seed Destruction

According to Breanne Tidemann, a field agronomy scientist with Agriculture and Agri-Food Canada based in Lacombe,...

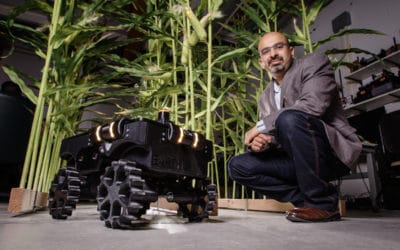

Ag robot speeds data collection, analyses of crops as they grow

A new lightweight, low-cost agricultural robot could transform data collection and field scouting for agronomists,...

Becoming One with the Machine

This new seeding innovation is one example of how new ideas are transforming precision ag. Agriculture – like all...