A lot has changed since the Camrose County Seed Cleaning Plant was built. Where grain trucks were once used to haul...

Seed Plant

Upgrading the Mountain View Seed Cleaning Plant in a Pandemic

Despite pandemic delays, Mountain View Seed Cleaning Plant managed to upgrade and expand its seed cleaning plant. When...

Westlock Seeding Cleaning Co-op is Upgrading their Seed Plant

Westlock Seeding Cleaning Co-op has taken on a massive new project — building a whole new plant. Over the years...

The Plant Upgrade of the Century for the Town of Three Hills

The Three Hills and District Seed Cleaning Plant has operated since the ‘50s, with a new upgrade on the horizon....

Community Helping Community at the Manning Seed Cleaning Plant

The Manning Co-operative Seed Cleaning Plant may be older, but the community is working together to upgrade and keep...

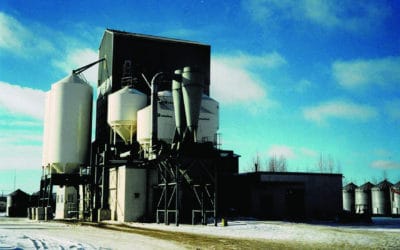

Building a Sense of Community at Bashaw Seed Cleaning Co-op

The Bashaw Seed Cleaning Co-operative built a new seed cleaning plant, which increased capacity, in 2018. Photo:...

Broadening Appeal

The Provost Co-operative Seed Cleaning Plant is boosting its business by drawing farmers from farther away. Leon...

Paying Attention to the Basics for 36 Years

A good crop starts with good seed, says the manager of Battle River Seed Cleaning Co-operative. Mark Kaese has been in...

Wetaskiwin Seed and Grain Co-op: Open for Everyone and Everything

When Wetaskiwin area farmers head to town to grab a burger, see a movie or do a little shopping, they have the option...

The Taber Seed Cleaning Co-op: Staying Ahead of Demand

After doubling Taber Seed Cleaning Co-op’s seed processing capacity five years ago at its Fincastle location, Joe...