Cereal crops that fix their own nitrogen? Achieving this dream could result in major benefits for agriculture and the environment.

Scientists around the world are pursuing this goal, including a group in Alberta. The Lethbridge-based researchers have already made impressive advances towards developing nitrogen-fixing triticale plants as a first step to creating other nitrogen-fixing cereals.

“The idea of nitrogen-fixing cereals is not new. The discovery in the late 1880s of symbiosis between nitrogen-fixing bacteria and legumes spurred the eventual question of whether it is possible in non-legume plants, including cereals. However, the path from the idea to its successful realization is in this case quite bumpy,” says Dr. Alicja Ziemienowicz, a research biologist with Agriculture and Agri-Food Canada (AAFC) and an adjunct professor at the University of Lethbridge. She is co-leading this nitrogen fixation research with her AAFC colleague Dr. François Eudes.

“There are three biotechnological approaches for biological nitrogen fixation in cereals, and all require genetic engineering of bacteria or plants or both,” she explains. “The first one is to create rhizobium-legume-like symbiosis in cereals; in other words, to convince rhizobia and cereals to form an interaction similar to the interaction of rhizobia with legumes. The second approach aims at improving bacteria that live inside cereal plants or in the soil right next to cereal roots so these bacteria can perform nitrogen fixation more efficiently.”

However, these two strategies would rely on the use of bio-fertilizer inoculants, which are not always as effective as crop growers would like and are not as convenient as having the trait in the seed.

“When I joined the team of Dr. François Eudes at AAFC’s Lethbridge Research and Development Centre about five years ago, we decided to take the third approach to the biotechnological solutions for the nitrogen fixation problem,” adds Ziemienowicz. “This approach is perhaps the most challenging one but also the most promising. It involves the direct transfer of bacterial nitrogen fixation (nif) genes into the plant.”

Ziemienowicz is an expert in this type of research and has been working on development of better technologies for plant improvement for over 20 years. She is excited to be applying her knowledge and skills to nitrogen fixation in cereals “to achieve practical and applicable outcomes in a research area that is so important for Canadian and global agriculture.”

“Many have labelled nitrogen-fixing cereal crops as the ‘holy grail,’” notes Lauren Comin, research manager with the Alberta Wheat Commission (AWC). “Nitrogen-fixing cereals could bring a lot of significant benefits. First of all is the benefit to the farmer’s profit. Obviously producers would save money by reducing input costs, and there could be time savings as well. Those benefits alone are enough for us to get excited.”

Ziemienowicz states, “Nitrogen fertilizers contribute about 20 per cent of cereal crop production costs, not including costs of fertilizer application: fuel, machinery, labour. Cereal crops capable of fixing nitrogen for their own needs will reduce crop dependence on nitrogen fertilizers, and will increase their performance and productivity in nitrogen-deficient soils.”

Both Comin and Ziemienowicz point out that nitrogen-fixing cereals would also contribute to sustainability. “There is an ever-growing interest in sustainability from those on the farm and off the farm. Plants that could fix all or some of their nitrogen would mean fewer synthetic applications, less nitrogen loss to the atmosphere and less leaching into the waterways,” says Comin.

Ziemienowicz explains that not all of the applied fertilizer is actually used by the crop, and the unused portion can cause problems including pollution of water sources for humans, livestock and aquatic species, and emission of nitrous oxide, a very potent greenhouse gas. In addition, production of synthetic nitrogen fertilizers is very energy-intensive and generates carbon dioxide.

“So, although nitrogen fertilizers provide farmers with great tools to increase cereal crop productivity, they come with costs that are a burden both for farmers and the environment,” says Ziemienowicz. “It is generally recognized that the introduction of biological nitrogen fixation into cereals and other major non-legume crops would be one of the most significant contributions that biotechnology could make to agriculture.”

Substantial Progress

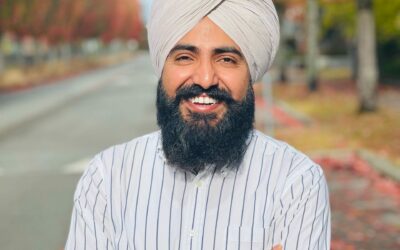

Eudes and Ziemienowicz began this research in 2014 with a two-year proof-of-concept study, funded by AWC and Alberta Innovates. Last year’s research was funded by AWC and the Saskatchewan Wheat Development Commission. Recently, the research was approved for three-year co-funding by all three of these agencies. In this upcoming work, Ziemienowicz and Eudes will be collaborating with AAFC wheat breeders Drs. Robert Graf and Harpinder Randhawa.

“We are open to investing in the full spectrum of available technologies,” notes Comin. “Technology changes really quickly in farming just as in any other industry. So we need to make sure that Alberta producers have every possible tool in their toolbox and that they keep up with technology changes.”

Ziemienowicz and Eudes’ research so far has involved triticale. “Most procedures that we employ in this project work more efficiently in triticale than in wheat,” says Ziemienowicz. “Once we obtain nitrogen-fixing triticale, we will transfer this trait into wheat using interspecies breeding techniques. Moreover, lessons learned from development of this trait in triticale will help us to apply it to other crop species.”

In the initial stage of their research, the research team developed tools needed for this work including an AAFC nifcluster, peptide nanocarriers, DNA delivery technology, microspore culture and regeneration, selectable markers and selection procedures, and a nitrogen-fixation assay for plant cells.

Their creation of the AAFC nifcluster is a good example of the important advances they are making. Ziemienowicz explains the ability to fix atmospheric nitrogen is limited to a small number of organisms including certain bacteria. These nitrogen-fixing organisms have about three or four genes responsible for producing the nitrogenase enzyme, which converts atmospheric nitrogen gas into ammonia, and about 10 to 12 genes that produce co-factors needed for nitrogenase activity.

“Prior to our work, biotechnologists were able to deliver only two out of 16 essentialnifgenes into plants. Recently, an Australian group reported delivery of 16 nifgenes, but each gene individually. In addition, both research efforts were done in tobacco as a model plant, and not in cereals,” she says.

“The AAFC nifcluster that we developed contains all 16 essential nifgenes and two selectable marker genes (needed to maintain the nifgenes in the plant genome). The cluster was designed to allow expression of the bacterial genes in triticale and wheat plant cells.”

In the next stage of the work, the researchers used their tools to move the AAFC nifcluster into triticale cells. “We deliver the AAFC nifcluster into triticale cells using a unique nanocarrier developed by Dr. Eudes’ team, in particular by Dr. Trevor MacMillan. The nanocarrier is a group of cell-penetrating peptides that carry DNA cargo into a specific location in a plant cell,” explains Ziemienowicz.

“We chose plant mitochondria as the best delivery place because these plant organelles offer the most optimal environment for nitrogenase production and activity. We use microspore cells (precursors of pollen) because they can be relatively easily regenerated into entire plants.

“Once the cargo-carrier nanocomplexes reach their destination, the DNA is released and integrated into the mitochondrial genomes, and the nifgenes are expressed, which leads to nitrogenase production.”

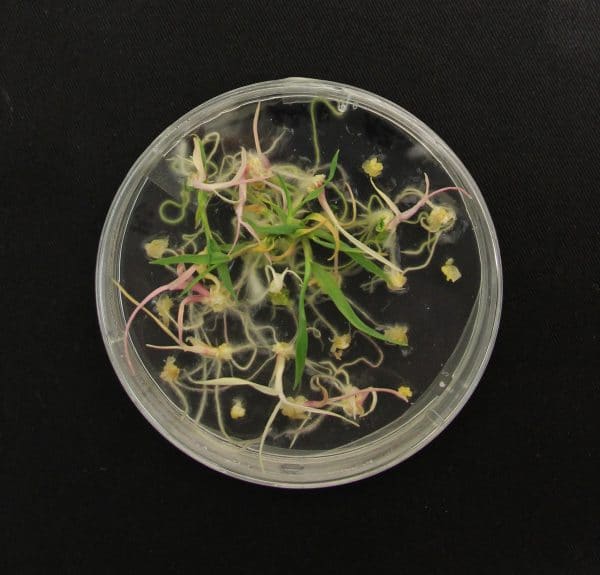

Recently, the researchers have shown that all the delivered nifgenes are indeed expressed in the triticale microspore mitochondria and that the nitrogenase enzyme is produced. Plus, they have demonstrated that the nif-enriched microspores definitely fix atmospheric nitrogen. The research team is now working on regenerating nif-enriched triticale plantlets.

If all goes as expected, they will produce triticale plants that have all the characteristics of the triticale parent plus the ability to fix nitrogen.

Ziemienowicz thinks it will take at least 10 more years to develop nitrogen-fixing wheat. “We need about three years to produce and test the nitrogen-fixing triticale plants. Then, we need a few years to transfer the trait to wheat. Also, it takes years for commercialization of a plant with a novel trait.”

Looking Down the Road

Even though it is many years away, the path to commercialization could be as challenging as the scientific path to develop nitrogen-fixing cereals.

One factor will be regulatory requirements for genetically engineered (GE) products. In Canada, the Canadian Food Inspection Agency (CFIA) evaluates all plants with novel traits for safety to the environment before they can be grown or fed to livestock. The CFIA website states: “The CFIA defines a plant with a novel trait (PNT) as a new variety of a species that has one or more traits that are novel to that species in Canada. A trait is considered to be novel when it has both of these characteristics: it is new to stable, cultivated populations of the plant species in Canada; and it has the potential to have an environmental effect…. Novel traits can be developed through various techniques, including, but not limited to, genetic engineering. Examples (other than genetic engineering) are mutagenesis, gene editing, cell fusion, and traditional breeding….This product-focused approach means that not all PNTs are developed through genetic engineering, and that not all products of genetic engineering are PNTs.”

“The Canadian ‘plants with novel traits’ approach is different from much of the rest of the world. [In Canada] it doesn’t really matter what process you used [to introduce a trait]; it’s whether it is a new trait that has never appeared before,” explains Cam Dahl, president of Cereals Canada Inc., a not-for-profit organization that brings together partners from all sectors of the cereals value chain.

“However, there would be some significant regulatory hurdles [for GE nitrogen-fixing wheat] in other markets like the EU or Japan because of the unfounded public perception around recombinant DNA technology.”

From Dahl’s point of view, recombinant DNA technology has provided great benefits, both economic and environmental, in crops like corn, soybeans and canola. But he is uncertain about what the cereals industry could do to change negative public perceptions of the technology. “That’s a question I have been asking for 20 years. I’m not quite sure of the answer, whether it’s an issue around technology in plant breeding or technology in pesticides, herbicides and fungicides. Very often public perception does not match up with the science and what science is telling us. The gap between scientific understanding and public perception sometimes can be very large, and that is difficult to cross.”

Dahl notes another consideration in commercialization. “We would have to ensure that, if a new product is commercialized, it would be done in a way that doesn’t jeopardize our current exports.” That would require such steps as obtaining regulatory approvals in importing countries and using identity-preserved systems to keep the GE grain separate from other grain. Another factor would be development of a policy on the low-level presence of GE crop material in grain shipments.

At present, many importing countries have a zero-tolerance policy if GE grain that has not been approved by the importing country is present at low levels in grain shipped to that country. This approach can seriously disrupt trade. Canada has been working with its international partners on alternatives to deal with this issue and has released a policy model to encourage international and domestic discussions on the way forward.

“Canada is a leader on the low-level presence issue,” notes Dahl. “Through the Canada Grains Council, we are very active on pushing forward with some solutions to that issue internationally.”

Despite the challenges, AWC hasn’t shied away from funding Eudes and Ziemienowicz’s work. “Investing in genetic engineering technology today does not mean that we’ll be harvesting a GE crop in August. Developing new varieties is really a long-term game. And depending on which novel traits we’re seeking, the benefits could far outweigh the perceived negatives,” says Comin.

“We are very excited about the prospect of nitrogen-fixing wheat. A made-in-Alberta solution would make it all the more exciting, especially a solution that we are part of,” she adds. “When we first invested in the project we did consider it high risk, but the potential benefits are significant. And we also had to consider the potential discoveries that could be made throughout the research that may also have applications that solve other problems that producers encounter. So even if the benefits wouldn’t apply to wheat but maybe another crop, these serendipitous discoveries could have a high value as well.”