With the technology available today, farmers are increasing their production. Seed treatments are among the newest technologies available — by helping seed get the best possible start, they are helping farmers grow more from less.

There are several best practices producers can follow to get good yields — proper crop rotations, good disease and insect management, seeding in ideal conditions and consistent seeding depth. However, it’s easy to fall short on one or more of these each growing season, and that is where seed treatments come in.

“Seed treatments should be considered an insurance policy. If you have ideal conditions at seeding, then the seed treatments may not pay. However, most springs do not provide those ideal conditions,†says Harry Brook, a crop specialist with Alberta Agriculture and Rural Development.

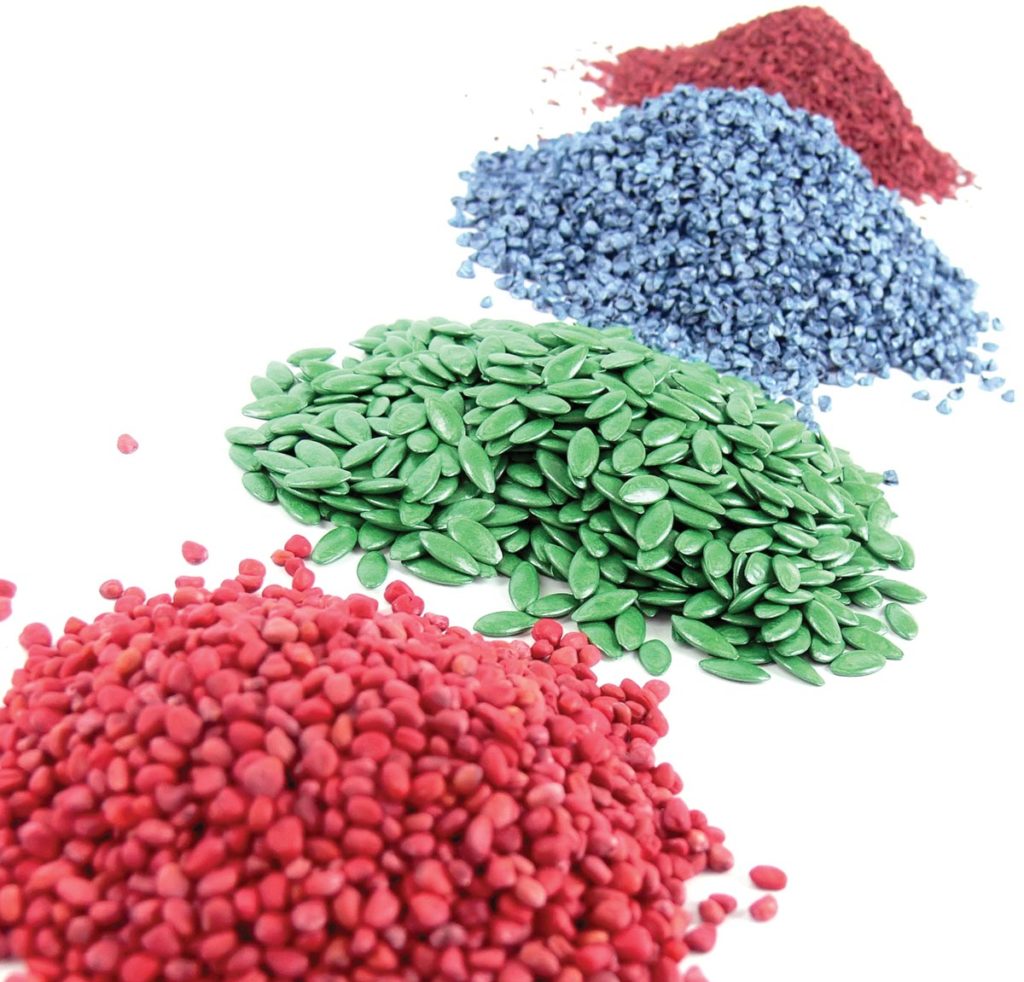

A seed treatment is a chemical or biological substance or physical process applied to seeds or seedlings to protect against insects, seed and soil-borne diseases and certain weather conditions such as frost, drought or flooding. By protecting the seed from early-season stressors, seed treatments help seeds reach their full genetic potential.

The primary role of any cereal seed treatment is to improve germination and emergence, and get young seedlings established through to the two- to four-leaf stage. At that point, the plants should have developed root and stem structures strong enough to outgrow further seedling disease attack.

Brook says seed treatments protect the seed from pathogens in the soil for about two weeks and then their efficacy declines. “Cool, wet, slow springs should give you a benefit using seed treatments,†he says.

Product Pipeline

A wide variety of seed treatments are currently available, and these products have come a long way in recent years. Some of the newest products boast significantly lower application rates than older products, operate via multiple modes of action to control more diseases and/or insects, and are available in ready-to-apply formulations.

“Since we released our first seed treatment in 1991, the needs of growers have changed a lot with continuous cropping and new crop rotations,†says Ted Labun, seed treatment specialist for Syngenta Crop Protection Canada. “We kept adding to our first solution, but now we’ve taken all those solutions and put them into one solution that’s easy to apply.â€

Labun is referring to Syngenta’s new Vibrance Quattro seed treatment, which contains four fungicides in one product and comes in a ready-to-apply formulation. The company also offers Cruiser Vibrance Quattro which has the Cruiser insecticide for wireworm protection.

Both products can be applied by commercial seed treaters, but are also available in a convenient, pre-mix formulation that can be applied on-farm without the requirement of a closed system.

Bayer CropScience also launched two new seed treatments this year. Raxil PRO is a new cereal seed treatment that combines the power of three fungicides in an easy-to-apply micro-dispersion formulation. Raxil Pro Shield incorporates the systematic and contact disease protection from Raxil with the plant health benefits and wireworm protection of Stress Shield.

Bayer has also recently launched the SeedGrowth brand, which represents the company’s four segments of seed treatment expertise: products, equipment, services and coatings. “Through Bayer SeedGrowth, farmers get support beyond just seed treatments to the quality and life of their seed and crops,†says Derrick Rozdeba, manager, integrated communications for Bayer. In 2014, Bayer partnered with Ag Growth International (AGI) to co-design the STORM Seed Treater for computerized, self-adjusting/metered, in-yard seed treatment for cereals.

Meanwhile, in the fall of 2014 Nufarm Agriculture was named the exclusive distributor of Valent Canada’s NipsIt seed treatments for on-farm use in Canadian markets.

“Seed treatments should be considered an insurance policy. If you have ideal conditions at seeding, then the seed treatments may not pay. However, most springs do not provide those ideal conditions.â€

—Harry Brook

NipsIt INSIDE is an insecticide seed treatment containing the active ingredient clothianidin, offering Canadian wheat growers protection of key insects, including wireworms, through contact and super-systemic activity. According to the company, NipsIt INSIDE stays in the seed/root zone longer than other insecticide seed treatments due to its lower water solubility.

A second product, NipsIt SUITE, is an all-in-one seed treatment containing the fungicidal active ingredients metconazole and metalaxyl, and insecticidal active ingredient clothianidin. Metconazole is a new fungicide seed treatment which provides superior protection against key seed and seedling diseases incited by seed-borne and soil-borne fungal pathogens such as the bunt and smut fungi, seed rot and seedling diseases caused by fusarium and rhizoctonia, says the company.

Since releasing its Insure Cereal seed treatment in early 2013, BASF Canada has been reminding growers about the benefits of using seed treatments.“By using a seed treatment with plant health benefits, crops can get off to a good start in spring,†says Russell Trischuk, technical marketing specialist, functional crop care for BASF Canada. Through 2011 and 2012, BASF conducted an extensive trial program using Insure. In 30 trials for wheat, Insure-treated seed had a two-bushel increase over competitors. In barley, the increase was three bushels and in oat it was more than a four-bushel advantage for the Insure-treated seed. Insure is a ready-to-use seed treatment with three modes of action: pyraclostrobin, triticonazole and metalaxyl.

Application Options

No matter how good the product, it can only be effective if applied evenly and at the proper volume to all sides of each and every seed. While getting seed treated commercially might be more expensive than treating on-farm, the payoff from a job done right can be worth the extra cost.

Brook says producers should avoid drip and gravity-fed applications as they result in inconsistent and unreliable coverage. For best results, he recommends buying pre-treated, certified seed, or using a good on-farm seed treater.

“On farm application is convenient, but to maximize the effectiveness of the fungicide, it needs to be on every seed. Most on-farm applicators can’t do as good a job getting an even coating on the seed as a seed treater in the local seed plant,†he says. “Many producers use their local seed cleaning plant to apply the seed treatment because of this.â€

“What is really important is that the quality of application is the best it can be. That is critical for field performance.â€

—Ted Labun

According to Labun, Syngenta supports both commercially treated seed and on-farm application. “What is really important is that the quality of application is the best it can be. That is critical for field performance.â€

Labun says the application method really depends on the crop. “For pulses and cereals we recommend both on-farm applications and commercial application, but canola is much more challenging to treat so we recommend growers only go through commercial treating for canola,†says Labun.

If a producer chooses to go the on-farm route, Labun says they have lots of support available to them. “We have five seed treatment specialists in the field that help with application best practices. Last year we held a clinic in Regina to train producers. We brought in five pieces of equipment, treated seed and talked about safety and proper equipment. We also hold grower meetings where we bring equipment in and do some training,†he says. “The quality of application is critical to see field performance; poor treatment isn’t going to get the return on investment that producers need.â€

Julie McNabb